WHY CODESYS?

With CODESYS you have the right tool for control system integrators, machine builders, device manaufacturers and end users.

Here are some facts:

- Faster and less expensive than a classic PLC, the CODESYS system can increase the production capacity of a machine without touching any mechanical processes.

- The CODESYS automation software can help to improve quality, reduce energy, waste, and costs for maintenance with no change in suppliers, capital expenditures, or personnel in factories by combining new IIoT technologies with proven PLC programming and hardware independence.

- Over 500 companies implemented CODESYS as standard in their products.

- Programmers worldwide value the work with the IEC 61131-3 automation software which covers the six global standard programming languages.

- The CODESYS automation software can be easily downloaded and is free of charge with full features.

- Every month more than 140,000 registered users download tens of thousands of add-on packages from the CODESYS webstore.

Tens of thousands of users today rely on CODESYS – the leading software platform on the market for IEC 61131-3-compliant project engineering. They work with the tool for automating factories, plants, mobile machinery, power generation and distribution systems, as well as buildings and processes.

About 500 manufacturers of programmable automation devices provide users with an extensive pool of compatible devices – for all kinds of industrial applications.

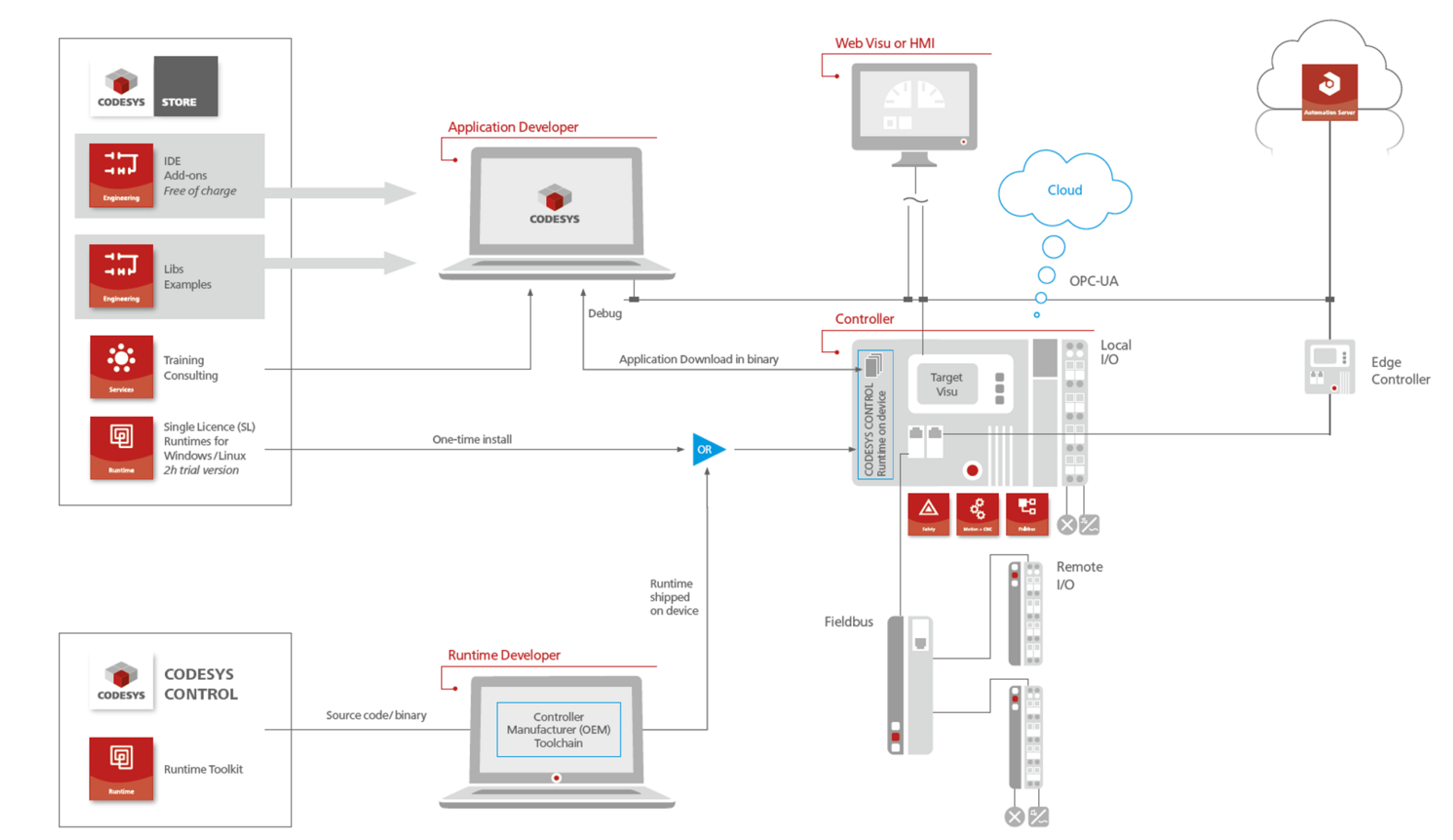

CODESYS combines classic PLC programming with the capabilities of a professional software for development, commissioning, and management of automation tools. Without any additional tools, the entire application can be configured, programmed, tested, and operated in a single user interface – including typical engineering tasks:

- Configuration of different fieldbus and real-time Ethernet systems

- Creation of modern visualization screens for operating modular units and complete machines, plants, and systems

- Planning and execution of complex applications for motion control, CNC, and robotics

- Programming of safety applications in accordance with DIN IEC 61508 SIL2/3

- Connection of industrial controllers to an existing infrastructure, for example consisting of PLC, DCS, server or cloud systems

- Administration of the control landscape with a cloud-based server platform

CODESYS RUNTIME Standard hardware platforms

- Any kind of intelligent devices (embedded or PC-based)

- Device Manufacturer independent

- ARM/Cortex on Linux, VxWorks

- x86 with Linux, Windows,VxWorks, QNX

- Power Architecture (PowerPC) with Linux, VxWorks

- Operating System independent

INNOVATIVE AND FLEXIBLE PRODUCTS

SOFTWARE EXPERTISE FOR MORE EFFICIENT WORK

A team of over 150 computer scientists and engineers stand behind CODESYS, developing, testing, maintaining, and marketing the system and all add-on components. Based on decades of experience in different areas of industrial automation technology, new features and extensions are developed continually for making day-to-day work easier and faster.

USERS BENEFIT IN MANY WAYS FROM THIS EXPERTISE:

- With every new CODESYS version

- Through practical trainings for various tasks

- Through add-on products for greater efficiency

- Through task-specific consulting

PRODUCTS, TRAININGS AND SERVICES

The CODESYS Store offers user products, such as addon tools for the CODESYS Development System and SoftPLC systems for popular device platforms.

Trainings by experienced specialists increase the effectiveness when working with CODESYS – for both beginners and experienced users alike.

Decisive optimization of the workflow in all phases of engineering – this is the aim of customer-specific consulting and development services

SOFTWARE PRODUCTS FOR USERS

The CODESYS Development System is the free-of-charge IEC 61131-3 development interface for users. The tool includes all functions for the day-to-day work of automation specialists. Seamlessly integrated add-on products supplement, when required, the already extensive system features.

CODESYS BENEFITS

- Faster and more cost efficient than a classic PLC

- Hardware independent - no supply shortage!

- One platform for all machine types

- Very powerful - even the most complex machines or production processes can be realized

- Easy integration with third-party products due to supporting standard technologies

- Easy integration with standard IT-world systems (MES, ERP, databases)

- Effective remote control for deployment, service and maintenance

- Highly scalable, customizable and extendable - ready for the future